Integrity and quality shall always be the critical requirements for materials used in manufacturing, construction, and engineering. However, how can one be assured of materials that must be manufactured to strict safety, reliability, and durability standards? Material testing is the scientific discipline that deals with the methods and approaches used to evaluate the quality and characteristics of materials. This guide takes a deeper dive into what material testing is and the different types of material testing, and reviews an exhaustive list of materials that go through these strenuous tests. Whether you are a practicing professional, scholar, or inquisitive layperson, this article will provide you with a fundamental understanding of the procedures of material testing, which are vital to myriad fields. Join us as we unravel the intricate processes underlying innovation and craftsmanship.Click here to read more

Introduction to Material Testing

Introduction to Material Testing

Material testing is the procedure of inspecting materials to determine their quality, performance, durability, and suitability for specific uses. These materials are subjected to various controlled conditions to demonstrate their strength, flexibility, and endurance against other influencing factors. Testing ensures the techniques needed to certify that these materials are applied where necessary. Material testing is an essential step for construction, manufacturing, and aerospace industries—all sectors where assurance of reliability and safety are given topmost concern. These tests have ensured that new implementations are subjected to failure before they come into existence, thus joining the innovative progress with safety and quality.

What is Material Testing?

Material testing is a scientific process that analyzes the properties and characteristics of a material when subjected to specific conditions. It subjects materials to tightly controlled experiments to ascertain properties such as tensile strength, hardness, elasticity, and durability over the duration of the experiment. Contrasting the materials’ responses to pressures, temperature changes, and environmental factors enables engineers and scientists to determine if they meet the necessary standards and specifications required for the various purposes for which they are used in practice. This type of analysis is necessary to prevent the impending failure of materials in critical industries, which include safety, reliability, and innovation, while developing better and more sustainable materials.

Importance of Material Testing

Material testing is essential because it ensures materials used in various applications comply with safety, quality, and performance standards. By considering strength, durability, and resistance under various conditions, such as stress, temperature, and pressure, testing aims to predict the material’s behavior in real-world scenarios. It has been proven vital for preventing structural failures, enhancing product reliability, and driving innovation across various industries. The testing of materials also plays a crucial role in sustainability by enabling the development of more efficient and environmentally friendly materials; therefore, this is an engineering practice deeply rooted in the manufacturing industry.

Overview of Different Materials

Materials can be broadly grouped into four categories according to their properties and applications: metals, polymers, ceramics, and composites. Metals, including steel and aluminum, are known for strength, conductivity, and malleability, which are hence used in the construction, transportation, and electronics industries. Polymers, comprising plastics and rubber, are lighter and highly versatile, finding applications in packaging, household goods, and medical devices. Ceramics, such as glass and porcelain, are considered materials that offer great strength, heat resistance, and insulation, with their applications spanning aerospace, semiconductors, and design. Composites work by combining two or more materials, such as carbon fiber-reinforced polymers, to achieve the best balance of weight and strength. These materials are applied in larger quantities in cutting-edge technologies, sports equipment, and renewable energy applications. Each material type, in its way, caters to a special need and thus fuels innovation in diverse industrial areas.

Types of Materials

Types of Materials

Metals

Metals are tough and durable materials that are widely used in construction, transportation, and manufacturing. Conductivity-wise, they conduct heat and electricity well, including examples like steel, aluminum, and copper.

Polymers

Polymers are lightweight and flexible materials often encountered in plastics, rubber, and textiles. Since they can be varied, they are used in packaging, medical devices, and so on.

Ceramics

Ceramics are hard, heat-resistant materials manufactured out of inorganic compounds. They are used in various applications, including pottery, electronics, and aerospace components, which enhances their durability.

Composites

Composites are a group of materials engineered with two or more materials that retain their individual properties. Typical examples include fiberglass and carbon fiber, which are widely used in aerospace, sports equipment, and renewable energy systems.

Natural Materials

Natural materials, such as wood, cotton, and leather, are derived from plants, animals, or minerals. These materials are used in construction, textiles, and everyday products due to their availability and sustainability.

Metals

Metals are renowned for their strength, conductivity, and versatility, thereby forming the backbone of numerous industries. Common metals like steel, aluminum, and copper find applications in construction, transportation, and electronics due to their hardness and ability to withstand stress. Metals may be malleable and ductile, allowing them to be transformed into wires, sheets, or intricately shaped objects. Additionally, metals exhibit good thermal and electrical conductivity, making them useful for a range of applications, from wiring to heat exchangers. Additionally, metals are recyclable and, therefore, sustainable, as they can be recycled and reused without compromising their core properties.

Polymers

Polymers are versatile materials composed of long chains of repeating molecular units called monomers, possessing properties that make them indispensable in modern life. They can be categorized into natural polymers, such as cellulose and proteins, or synthetic polymers, including polyethylene and nylon. Polymers are lightweight, flexible, and resistant to corrosion, making them ideal for use in packaging, textiles, automotive parts, and medical equipment. Furthermore, their ability to be shaped and economical cost make them very important in diverse industries. Nevertheless, their durability sometimes causes environmental problems; therefore, there are stimulating attempts to find biodegradable and recyclable solutions to ensure sustainability.

Ceramics

Ceramics are non-metallic substances with an inorganic composition, generally shaped by means of heating and cooling processes. They are hard, have a very high melting point, and exhibit excellent insulating properties both thermally and electrically; thus, the service applications are far and wide in scope. They are used for construction, such as tiles and bricks, and for advanced technologies, including electronics, aerospace, and medical implantation. Chemical stability and corrosion resistance add to its versatility, which is restricted somewhat, however, due to brittleness. Present-day research is focused on enhancing the properties of ceramics to make the material compatible for use in energy storage and sustainable manufacturing molds.

Different Types of Material Testing

Different Types of Material Testing

Material testing is crucial for understanding the properties and durability of various materials. There are the main types of material testing:

Mechanical Testing ascertains a material’s strength, ductility, hardness, and impact resistance. The standard testing methods include tensile testing, compression testing, and fatigue testing.

Thermal Testing checks how materials respond to temperature changes, such as being thermally conductive, expansive, or thermally resistive.

Chemical Testing determines the chemicals contained in the material or their chemical stability, often with an emphasis on corrosion testing against environmental factors or testing resistance to specific chemicals.

Nondestructive Testing (NDT) checks for material properties without damaging the sample, using methods such as ultrasonics, X-rays, or magnetic particle testing.

Microstructural analysis examines the internal structure of materials to identify defects or uniformity, typically using microscopy techniques.

Each type of testing provides crucial information for choosing materials and designing their performance in specific applications.

Mechanical Testing

Mechanical testing evaluates the behavior of materials under physical forces to ensure they perform as required. Typical tests include tensile testing, wherein a material is stretched to its breaking point to measure its strength; compression testing, wherein materials are tested by engaging pressing forces; and impact testing, wherein a material’s electron absorption force under sudden load is tested. Additional tests include hardness testing, which measures resistance to indentation and scratching; and fatigue testing, which is a durability test that involves applying secondary cyclic stress to the material. These testing procedures provide the basic data to predict the behavior of materials, assess their quality, and select materials for specific applications.

Non-Destructive Testing

Non-destructive testing (NDT) collectively refers to a variety of techniques used to evaluate the properties of materials or components in systems without causing damage or impairing their future usability. Ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing are among the most typical forms of NDT. These methods are sufficiently crucial to an industry that depends on structural integrity: aerospace, construction, and manufacturing.

NDT caters well to modern-day industrial demands. For example, ultrasonic testing has historically been one of the most sought-after and widely practiced techniques in NDT due to its precision in pinpointing internal flaws or gauge variations. The phrases “automation in non-destructive testing” and “AI integration in NDT” in search results indicate a growing interest in enhancing efficiency, reliability, and real-time analysis during inspections. By capitalizing on research in NDT and emerging technologies such as machine learning, industries can ensure safer operations, fewer unexpected failures, and more effective resource allocation, all within the framework of safety standards and cost-effectiveness.

Destructive Testing Methods

By design, destructive testing damages or destroys the specimen to test its mechanical properties, such as tensile strength, for example, or perhaps toughness, hardness, fatigue limits, or some other mechanical variables tested after the specimen has undergone testing. Unlike non-destructive testing, these provide detailed, definitive data regarding a material’s behavior under extreme conditions to determine its structural and performance limits. Amongst the common types are tensile testing, which involves pulling a sample apart to measure at the breaking point; impact testing, which tests the material’s capability to absorb energy when sudden forces are applied; and hardness testing, which may entail different procedures where the material’s resistance to deformation by an indenter is measured. Although the techniques cannot preserve the tested specimen, destructive tests provide data essential for programs that enhance design, quality control, and material choice, ensuring reliability and durability in critical applications.

Common Testing Methods

Non-destructive testing techniques are used to evaluate specific properties of materials or structures without destroying the specimens. In doing so, NDT methods are fundamental to safety, reliability, and economic considerations in varied fields such as aerospace, construction, and manufacturing. These NDT techniques are:

Ultrasonic Testing (UT): Utilizes high-frequency sound waves to identify internal flaws or to measure thickness.

Radiographic Testing (RT): Uses X-rays or gamma rays to detect internal defects within materials.

Magnetic Particle Testing (MT): Highlights surface and near-surface discontinuities in ferromagnetic materials.

Liquid Penetrant Inspection (PT): Uses a liquid dye to reveal surface cracks, which backflow from minor pores to be cleared.

Visual Inspection (VI): The most basic and standard method, checking for visible defects in materials or components.

In this way, the technique provided for in NDT allows checking while maintaining the objects tested.

Compression Test

A compression test serves as a clustering force and a method by which materials show how they behave against compressive forces. A steadily increasing load is applied to a sample of the material during this test until the sample deforms or fails, imparting information about properties such as compressive strength, elasticity, limits of deformation, etc. This test is a principal type used in industries where the design of components must ensure operational stresses among construction, manufacturing, and materials science. By observing materials under compression, engineers and researchers could identify their suitability on specific applications and optimize their designs for safety and performance.

Bend Test

The bending test affects the ductility, strength, and fracture resistance of the material by forcing it to bend without breaking. It indicates how materials withstand deformation and stress within certain contexts, which is of utmost importance to the construction, aerospace, and manufacturing industries. Based on material behavior during bending, which could include crack formation, fracturing, or uniform bending, engineers can appraise how reliable and fit that material is for a certain practical use. The test results provide vital insight into the structural integrity of the material and material selection optimization in both design and production processes.

Deformation Analysis

Deformation analysis evaluates the response of materials to an applied force in terms of changes in shape, size, or structural integrity. It looks at stress-strain behaviors to identify elastic and plastic limits and determines parameters like yield strength and ultimate tensile strength. Using this information, engineers can anticipate performance under different loads to ensure materials resist real-life circumstances without breaking. Measuring and modeling accurately, deformation analysis is, from that standpoint, essential for resolving safety issues, improving designs, and optimizing material usage for several kinds of industries.

Material Testing Machines

Material Testing Machines

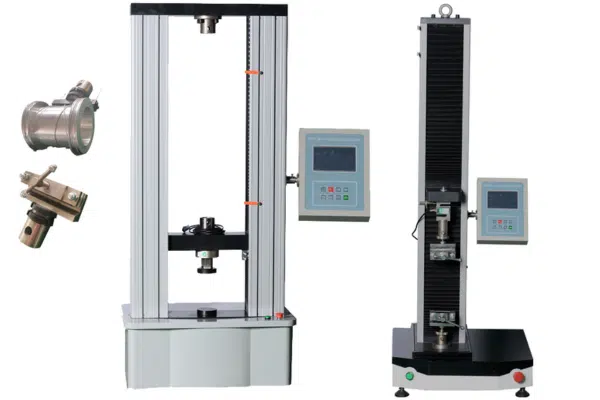

A material testing machine is any machine designed to determine the physical and mechanical properties of materials under given conditions. The common types considered are:

Universal Testing Machines: These versatile machines test tensile, compression, and bending stresses and are considered an important means of studying the strength and flexibility of materials.

Hardness testers are used to test the hardness of materials. They measure resistance to deformation using various methods, typically Brinell, Rockwell, or Vickers.

Impact Testing Machines: With impact testing machines, the material’s toughness and the ability to absorb sudden force are determined using Charpy and Izod impact tests.

Fatigue Testing Machines: These machines give repetitive stresses, thereby testing the endurance of materials subjected to cyclic loading, hence resistance to fatigue failure.

Non-destructive Testing Machines: It is an inspection procedure that does not damage the object, using techniques such as ultrasonic or X-ray imaging to locate flaws inside a sample or object.

These testing machines ensure quality, reliability, and safety in material engineering throughout construction, aerospace, and manufacturing.

Types of Testing Machines

Testing machines are the most commonly used tools for testing and evaluating the characteristics and behaviors of materials subjected to various conditions. Tensile testing machines determine the strength-to-load parameter or elongation-to-load parameter when checking durability. Compression testing machines are usually used to evaluate a material’s resistance against pressing forces, which is very much essential in construction and structural works. Impact testing machines observe material behavior on sudden force imparted upon it, testing for toughness in such environments where safety and reliability are paramount. Fatigue testing machines produce a repetitive stress pattern to study materials undergoing cyclic loading for an extended period, to predict life span, and thus prevent fatigue failure. Non-destructive testing machines like ultrasonic or X-ray methods, detect hidden flaws or weaknesses without compromising the integrity of the materials. Together, these testing machines ensure the safety, reliability, and quality of materials across diverse industries, such as aerospace, automotive, construction, and manufacturing.

Calibration and Maintenance of Test Machines

A regular calibration and maintenance process for test machines has been established to ensure their accuracy, reliability, and long-term service for various applications. It recommends calibration by checking the machine measurement against a standard reference and eliminating all sources of errors to achieve the exact required performance. Maintenance should be performed regularly to include inspections, cleaning, lubrication of moving parts, and replacement of worn-out components, thereby preventing sudden machine failure. A regular calibration and maintenance program helps reduce machine downtime, increase test result reproducibility, and ensure compliance with industrial requirements. Many organizations follow manufacturers’ recommendations, while others follow international standards such as ISO for systematic recording and scheduling of all calibration activities and maintenance, ensuring the right functioning and safe use of the equipment.

Frequently Asked Questions (FAQs)

What is a material test and why is it important?

Material testing is the practice of observing the physical properties of raw materials and their components under certain circumstances. Testing is important because it tells us if a material is fit for a particular application, meets quality standards, and does not prematurely fail. Engineers test for strength, flexibility, resistance, and other factors to select the best materials for construction and manufacturing. Such tests show what stress the material will undergo with time, and safety and performance rest on such knowledge. Material testing is thus a cornerstone for technological advancement and for ensuring the dependability of products.

What are the different types of material testing?

Material testing is a diverse field that encompasses various methods for evaluating the specific characteristics of a material. Some standard testing methods are mechanical-oriented tests to determine the mechanical properties of raw materials like tensile strength or ductility. We can also discuss non-destructive methods that are employed to test samples without causing any harm, whereas destructive material testing involves subjecting samples to specific conditions until they fail. Lastly, the compression test consists of some of the most common procedures in testing compressive resistance. These are very general classifications; however, each test is further customized to meet different industry standards and applications, allowing for a comprehensive analysis of materials.

What is involved in the compression test?

This compression test is an axial loading test conducted up to failure for ascertaining the behavior of materials. This test measures the material specimen’s capacity to resist compressive forces and its data rendering for compressive strength and deformation characteristics. During the compression test, a material specimen is placed in the test machine, where pressure is applied to the specimen until it ruptures or yields. The parameters obtained during testing are necessary for evaluating the performance of materials used in building and other structural components. The behavior of materials under compression, such as steel, must be understood for design and safety in engineering applications.

How does non-destructive testing work?

The non-destructive testing (NDT) comprises a set of methods used for material evaluation without causing any damage. This evaluation is vital for ensuring the integrity and reliability of a material and its components, especially in applications where safety is paramount. NDT can find flaws, measure the thickness of materials, and estimate the resistance of a material to various stresses. Some examples of techniques include ultrasonic testing, magnetic particle testing, and radiographic testing. By applying non-destructive means, industries can track their materials along time and prevent expensive collapse.

What are the applications of materials testing?

Materials testing has numerous applications in various industries, including construction, aerospace, automotive, and manufacturing. Testing will ensure that the raw materials, the components put together therewith, and the finished products meet the specifications and accepted performance criteria. Testing will, for example, identify the mechanical properties of raw materials, test their durability, and assess their suitability for specific applications. Anyhow, testing is essential in R&D, especially with the emergence of new materials. By understanding material behavior under various conditions, engineers can develop and improve product designs that lead to safer and efficient technologies.